| Sign In | Join Free | My enlightcorp.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My enlightcorp.com |

|

Brand Name : YASKAWA

Model Number : GP25

Place of Origin : CHINA

MOQ : 1

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 99+set+per month

Delivery Time : 4-6 weeks

Packaging Details : YASKAWA GP25 industrial robot arm standard wooden packing, WG:250 KG YRC1000 Controller standard packing, WG: 50 KG

Product Name : GP25 Material Cutting Trimming 6-axis industrial robot

Number of axis : 6

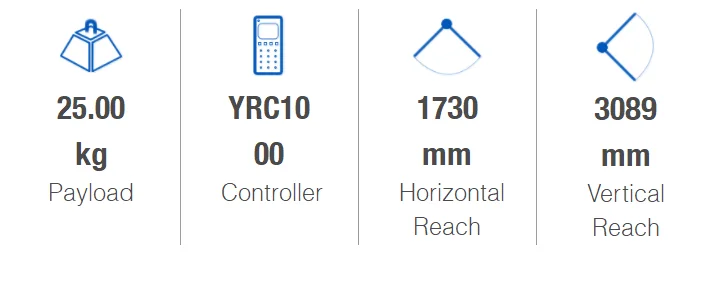

Max payload : 25 kg

Maximum reach range : 1730mm

Pose repeatability(ISO 9283) : ±0.06mm

Controller : YRC1000 controller

Mounting position : Floor, Wall, Tilt, Ceiling

Warranty : 1 Year

Yaskawa GP25 Die Cast, Dispensing, Material Cutting Trimming 6-axis industrial robot with YRC1000 controller

Main Specifications:

Model:GP25

Maximum reach:1730mm

Maximum payload:25kg

Pose repeatability:± 0.06mm

Number of axes:6

Weight:180 kg

GP25 Introduction:

Key Benifits:

1. High payload, axis speed and wrist allowable moment ratings.

2. Space-efficient design

3. Engineered for easy installation, operation and maintenance.

Achieve high transfer capability with highest payload, speed and wrist allowable moment in its class. Ideal for high-volume handling and packaging applications. Reduced-interference design permits close proximity to other robots and process equipment.

The GP-series robots offer improved acceleration/deceleration control for all robot positions resulting in overall improved productivity. The small footprint, slim arm design allows for minimum installation space and minimizes interference with peripheral devices. Installation is quick and efficient. A single cable is all that is needed to connect the manipulator to the controller, resulting in easy setup and reduced expenses for maintenance and spare parts inventory.

YASKAWA GP25 advantage:

· Increase your productivity with the fast and efficient GP25 robot.

. All axis speeds have been increased, some Over 40%, surpassing otherrobots in its class.

. Minimum acceleration/deceleration times provide high performance.

. Reduced interference design allows close proximity placement Of robots.

. Hollow upper arm provides optimal cable protection and longer life while simplifying programming. A 50 mm clearance through axes 4-6encloses the cable and protects it from wear, interference Or snagging.

. Patented double yoke upper arm design provides additional strength if the robot is crashed. Much stronger than other six-axis integrated cable designs.

· High wrist allowable moment for accurate and repeatable handling.

. Increased 25 kg payload, as well as increased moment and inertia ratings over previous models, allow larger and heavier loads to be carried by the robot.

. Single power and control cable reduces wiring time and increases work efficiency.

. New robot harness design for improved diagnostics and maintenance.

. Home position data can be saved without battery connection for easy maintenance.

. The GP25 has an lP67-rated wrist and an IP54 body standard. An XP (extra Protection) package that increases the body protection rating to IP65 is available.

. An anti-corrosive paint option is available for environments where harsh acidic Or alkaline cleaners are used, such as food processing facilities.

· The GP25 can be floor-, wall- or ceiling-mounted. Brakes are included on all axes.

· Compact YRC controller utilizes the light weight standard teach pendant with intuitive programming.

Applications:

Assembly, Die Cast, Dispensing, Material Removal, Material Cutting/Trimming, Material Handling, Pick and Place, IP65-67

Production Description

| Product Name | GP25 Die Cast, Dispensing, Material Cutting Trimming 6-axis industrial robot with YRC1000 controller for Yaskawa |

| Model | GP25 |

| Application | Assembly, Die Cast, Dispensing, Material Removal, Material Cutting/Trimming, Material Handling, Pick and Place |

| Maximum reach | 1730mm |

| Maximum payload | 25kg |

| Pose repeatability (ISO 9283) | ± 0.06mm |

| Number of axes | 6 |

| Mounting position | Floor, Wall, Ceiling |

| Weight | 180 kg |

| Protection rating | IP65-IP67 |

| Controller | YRC1000 controller |

| Motion range | |

| S | 180° to -180° |

| L | 155° to -105° |

| U | 160° tp -86° |

| R | 200° to -200° |

| B | 150° to -150° |

| T | 455° to -455° |

Company Profile

Our service

1.Swift delivery

For common parts, we can deliver the goods within 60 days

2.Original products

All the products we sell are from origin manufacturer. We will submit all the manufacturer documentation while we finish delivery.

3.Quality Assurance

4.Technical Support

Including inspection,repair and maintenance, we can give all kinds of technical support.

5.Quickly responce

Our staffs will keep 24h online and answer your question very quickly.

|

|

Material Cutting Trimming Lightweight Robotic Arm With 25kg Maximum Payload Images |